The future of U.S. battery manufacturing took a step forward in North Texas earlier this year, with one of the most advanced battery prototype facilities in the country already up and running. For many outside the industry, it has flown under the radar. But what’s taking shape inside is set to power U.S. authority in energy storage.

At the University of Texas at Dallas, a quiet launch this spring marked the opening of BEACONS: the Batteries and Energy to Advance Commercialization and National Security center. Though it wasn’t formally announced until June, the facility has been years in the making.

With $30 million in Department of Defense funding and more than $200 million in private capital behind it, BEACONS represents a federal-academic-industry push to scale America’s battery manufacturing capabilities for national defense, commercial innovation, and energy resilience.

The launch comes as supply chain independence has become a top national priority.

Major General Edmond “Miles” Brown, in fatigues, of Army Futures Command visits the BEACONS facility at UT Dallas during a May 28 stakeholder briefing and tour focused on the university’s innovations with defense applications. [Photo: UT Dallas]

Born from a “battery research dream team”

BEACONS works with U.S. companies to develop and scale transformative battery technologies from raw materials to systems-level applications. That includes everything from grid storage to consumer electronics to high-performance defense systems, according to UT Dallas.

First announced in fall 2023, BEACONS was established as part of the Department of Defense’s Manufacturing Capability Expansion and Investment Prioritization (MCEIP) initiative.

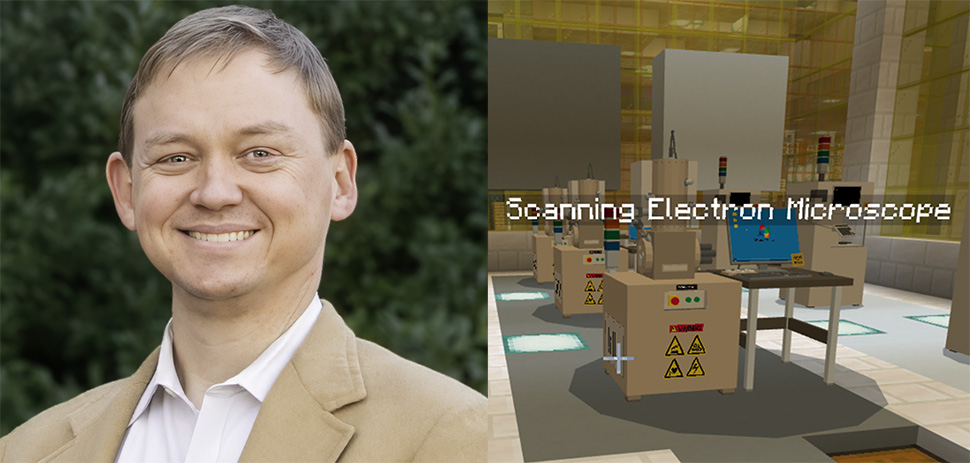

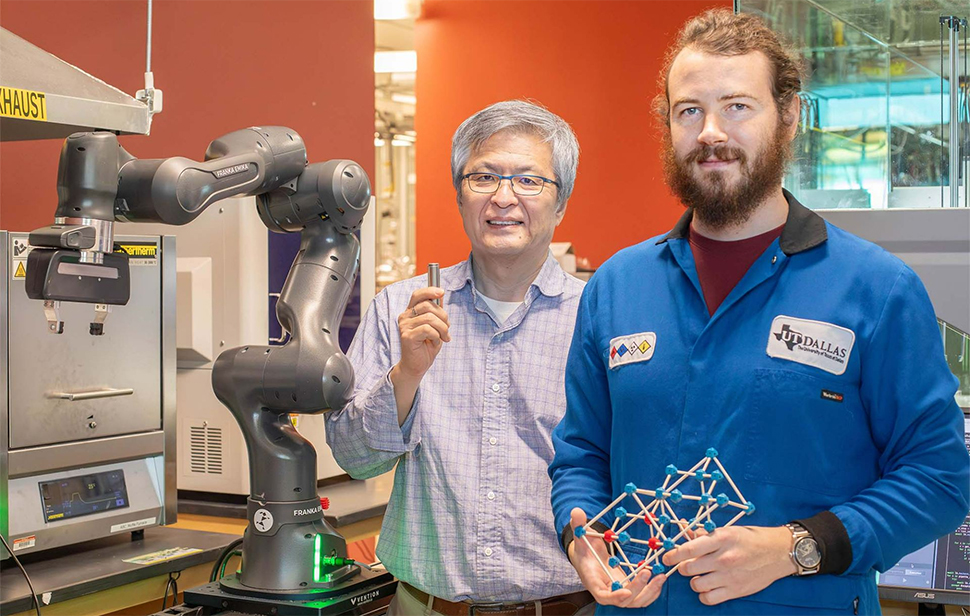

“We identified a unique area that satisfies the Department of Defense’s needs for battery technology,” Kyeongjae Cho, director of BEACONS and professor of materials science and engineering at UT Dallas, said at the time.

The investment, he added, supports collaboration with industry partners to ensure the reliable, domestic production of lithium-ion cells and advanced battery packs for commercial and defense systems. BEACON is also part of the Pentagon’s Pathfinder and SCALE programs, which are designed to accelerate the adoption of dual-use technologies and strengthen U.S.-based supply chains.

Cho was part of what UT Dallas has called a “battery research dream team,” which helped charge up the university’s momentum with a $600,000 National Science Foundation grant in 2023. Just a few months later, the team of experimental and theoretical researchers secured the DOD award, the largest-ever federal award to the institution. In less than a year, the researchers had progressed from concept to funding, working across lithium-ion, solid-state, and aqueous zinc-ion chemistries to tackle challenges from safety to scalability.

“This isn’t just academic. It’s about moving technology into the field,” Cho told industry publication Utility Dive in June.

“Our facility is designed for domestic companies who need to prototype and scale.”

Kyeongjae Cho, who holds a doctorate in physics from the Massachusetts Institute of Technology, directs the BEACONS facility and leads the university’s battery technology initiative. [Photo: UT Dallas]

Inside the BEACONS center

Local, state, and federal officials recently toured the facility alongside industry partners.

From ultra-dry labs to rapid prototyping lines, the 15,000-square-foot center was designed to help companies fast-track battery innovation, scale domestic production, and reduce dependence on foreign suppliers.

“This is a milestone not just for battery technology, but for the future workforce,” said Dr. Joseph Pancrazio, vice president for research and innovation at UT Dallas and a co-principal investigator of BEACONS. “We look forward to working with industry partners to fast-track energy storage innovation.”

The initiative is a collaboration between UT Dallas, Associated Universities Inc., and LEAP Manufacturing—a consortium of battery and energy storage companies focused on accelerating domestic battery innovation and manufacturing.

Matthew Bergschneider, a Ph.D. candidate in materials science and engineering and Eugene McDermott Graduate Fellow at UT Dallas, explains the layout of the 3,500-square-foot dry room during the BEACONS open house. [Photo: UT Dallas]

Specialized environments are crucial for battery chemistries, where even trace amounts of moisture can disrupt the development process. BEACONS includes a 3,500-square-foot dry room kept at below 1% humidity—drier than most deserts—and a 400-square-foot solid electrolyte room kept at less than 0.25% humidity for processing highly sensitive solid-state battery materials.

In addition to prototyping, BEACONS uses AI tools and geospatial modeling to track minerals such as lithium, cobalt, and nickel. The goal is to give companies better visibility into their supply chains and help build battery systems in the U.S.

The facility is also a workforce development engine, housing dedicated areas for workforce training and collaboration. UT Dallas is partnering with five local community colleges to create new energy certificate programs and launching undergraduate courses to train both students and working professionals.

UT Dallas President Richard C. Benson (left), who will step down in August after nine years of leadership, and President Emeritus David E. Daniel joined stakeholders and industry leaders at the April open house for the new facility. [Photo: UT Dallas]

Next-gen battery tech, supply chain resilience

By design, BEACONS sits at the intersection of applied research, scalable manufacturing, and national security. “We don’t pursue research for knowledge alone,” according to the its standalone website. “We fill critical gaps in manufacturing by helping prototypes transition into full-scale, cost-competitive production.”

The center said it offers IP-secure prototyping labs that let startups and manufacturers rapidly develop, test, and protect new technologies.

Although the BEACONS center officially opened in April, the program was already producing results.

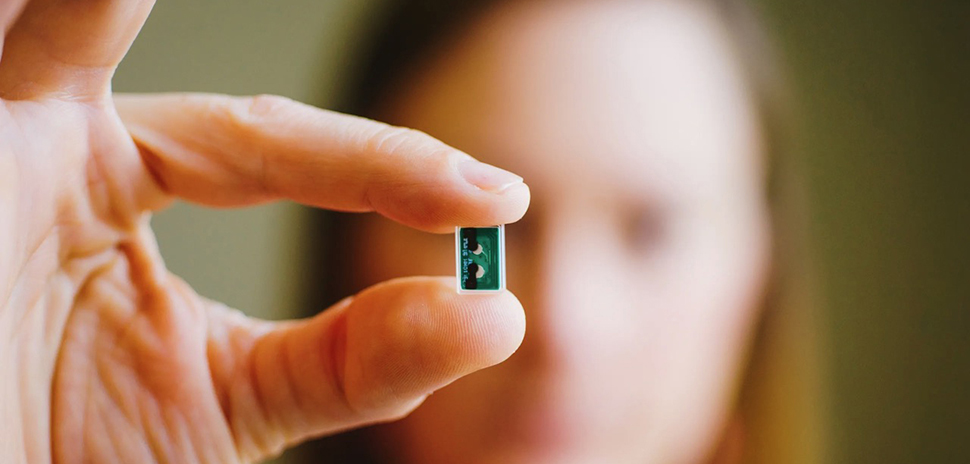

Earlier in 2025, UT Dallas researchers published findings in Advanced Energy Materials that shed light on a long-standing barrier to next-gen lithium-ion batteries: why lithium nickel oxide (LiNiO₂) breaks down over time. The material has long shown promise for powering electric vehicles, phones, and grid storage, they said, but has remained commercially out of reach due to its instability.

UT Dallas researchers traced the root cause to a chemical reaction involving oxygen atoms that makes the material prone to cracking. Their proposed fix: reinforce the structure by adding positively charged ions that act like internal supports, or “pillars.” They’re now testing that design in the lab, with the goal of eventually manufacturing pillared lithium nickel oxide batteries at scale.

Kyeongjae Cho (left), professor of materials science and engineering, and doctoral student Matthew Bergschneider found that a chemical reaction involving oxygen atoms in lithium nickel oxide causes the material to become unstable and crack. [Photo: UT Dallas]

“The degradation of batteries made using LiNiO₂ has been a problem for decades, but the cause was not well understood,” said BEACONS director Cho. “Now that we have a clear understanding of why this happens, we’re working on a solution so the technology can be used to provide longer battery life.”

But Cho emphasizes that BEACONS’ stakes extend beyond consumer applications to supply chain and defense.

“We want to have that supply chain resilience and independence from the Chinese supply chain,” Cho told Utility Dive. “Even if things really go bad and China decides to cut off all of these critical mineral supplies, the [domestic battery supply] will not be impacted… especially those going to defense applications.”

In March, BEACONS co-hosted a strategy session with the Wright Brothers Institute in Dayton, Ohio, focused on the role of batteries in unmanned aerial systems—a top defense priority, Utility Dive reported. And the program continues to add partnerships designed to fast-track innovation, from grid-scale storage to battlefield energy systems.

‘It’s a starting point’

As Tom Campbell, co-founder of LEAP Manufacturing and a co-principal investigator for BEACONS, put it, the facility’s mission is both practical and long-term: to provide hands-on learning for students and connect researchers with industry partners advancing energy storage across applications.

“Today it’s not a finish line; however, it’s a starting point,” Campbell said. “This is about building, making, and competing globally without relying on foreign supply chains.”

Don’t miss what’s next. Subscribe to Dallas Innovates.

Track Dallas-Fort Worth’s business and innovation landscape with our curated news in your inbox Tuesday-Thursday.